In the world of industrial automation, mechanical design, and robotics, precision and efficiency are everything. Pneumatic systems — those that use compressed air to power machines — have long been essential in factories and vehicles. But a new advancement is reshaping this field: Tribupneu.

It is an emerging innovation that blends the science of tribology (friction and surface interaction) with pneumatics (compressed air mechanics). This fusion creates smoother, quieter, and more efficient systems, offering better performance and longer life for machinery.

What Is Tribupneu?

The term Tribupneu combines two ideas — “tribo,” meaning friction or wear, and “pneumatic,” meaning air-powered motion. At its core, Tribupneu represents a design philosophy that reduces energy loss and improves mechanical reliability by controlling both friction and airflow.

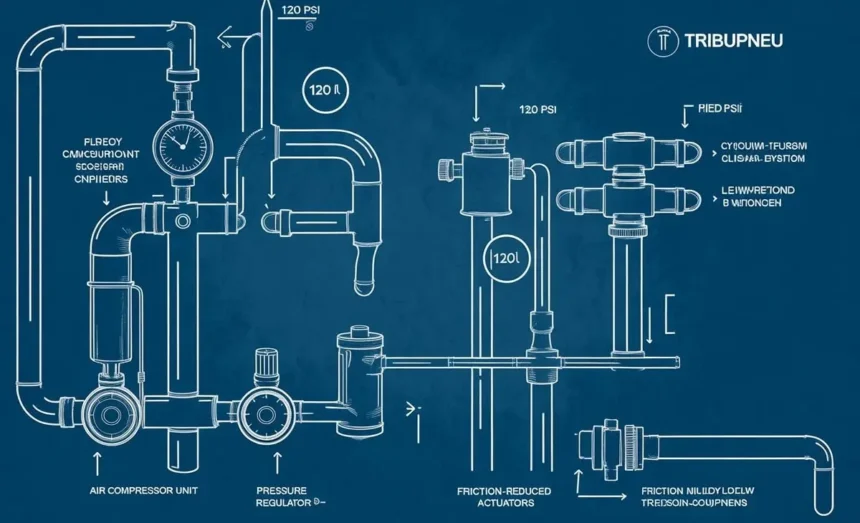

Traditional pneumatic systems work by sending compressed air through valves, pipes, and cylinders to move components. While effective, they often waste air, generate noise, and experience wear over time. Tribupneu technology improves this by using advanced materials, surface coatings, and intelligent air management systems to minimize resistance and loss.

It’s more than an upgrade — it’s a shift toward sustainable and precision-based pneumatics.

How Tribupneu Works

It operates on two main scientific foundations — the study of friction and the use of pressurized air. Tribology focuses on how surfaces interact, while pneumatics focuses on the movement of air that drives mechanical action. When these two fields merge, the result is a system that self-regulates pressure, reduces internal heat, and prolongs component life.

Imagine a robotic arm in a manufacturing plant. In standard systems, air leaks or uneven pressure can cause jerky movements. In a Tribupneu system, micro-textured surfaces and air-flow balancing mechanisms ensure smooth motion, precise control, and minimal energy waste.

This integration makes machinery more stable, efficient, and environmentally friendly.

Advantages of Tribupneu

The benefits of Tribupneu reach across both industrial and environmental domains. Systems designed under this principle consume less energy, operate more quietly, and last longer.

By reducing the friction between moving parts, the technology helps machines maintain performance without frequent maintenance. It also minimizes wear, meaning parts need fewer replacements — lowering costs and downtime.

Another key advantage is precision. Because Tribupneu systems can finely control airflow and resistance, they are ideal for robotics, automotive components, and sensitive instruments that require accuracy.

In essence, it brings together three crucial outcomes: efficiency, longevity, and sustainability — all essential for modern engineering.

Real-World Applications

It has potential in many areas of modern technology. In automotive design, it can improve braking and suspension systems by providing smoother, more responsive pneumatic control. In robotics, it enables quiet, precise motion critical for assembly lines or medical equipment.

Factories that use pneumatic tools can see a clear difference in energy consumption and maintenance cycles. For example, a production line using Tribupneu-equipped cylinders can operate with less air pressure while maintaining the same output. Over time, this reduces energy costs and environmental impact.

Even in aerospace and research industries, where accuracy is non-negotiable, Tribupneu offers enhanced reliability and reduced vibration — both essential for testing and measurement systems.

Maintenance and Reliability

One of the defining features of Tribupneu systems is their durability. By reducing mechanical friction, these systems experience less wear on seals, valves, and pistons. As a result, maintenance intervals can be extended significantly.

Routine inspection still matters, especially for air-tight seals and pressure sensors, but overall upkeep becomes simpler. Cleaning surfaces and checking air calibration are typically enough to keep the system running smoothly.

In industries where downtime equals financial loss, this improvement alone can justify adopting Tribupneu-based designs.

Engineering Perspective

From an engineering standpoint, Tribupneu represents a bridge between classical mechanics and digital innovation. Traditional pneumatics relied on mechanical efficiency alone, while modern systems like Tribupneu integrate smart sensors and adaptive surfaces to adjust pressure automatically.

The underlying science depends on creating materials that respond predictively — reducing drag when motion begins and maintaining balance as speed increases. Such innovations make machines quieter, safer, and more consistent.

This approach aligns perfectly with the current industrial goal: building systems that are self-regulating, low-maintenance, and energy-aware.

Environmental and Economic Impact

Beyond performance, it has clear environmental value. By reducing air loss and power requirements, it lowers energy use and carbon emissions. Because components last longer, there’s less material waste from replacements and repairs.

For companies, the economic advantage is equally strong. Less energy means lower operational costs, and less maintenance means fewer interruptions to productivity. Over time, these savings can significantly outweigh the initial investment in Tribupneu technology.

This makes it both a green and financially sound innovation.

The Future of Tribupneu

As automation and smart manufacturing continue to evolve, Tribupneu is expected to become a key part of next-generation systems. Engineers are already experimenting with adaptive friction surfaces that can adjust in real time, optimizing performance depending on environmental conditions.

In the future, Tribupneu may be integrated into AI-controlled pneumatics, where data from sensors will automatically fine-tune airflow and friction to maximize efficiency. This could revolutionize not only factories but also transportation, healthcare devices, and renewable energy systems.

The concept shows how deeply intertwined material science and digital control have become — working together for cleaner, more intelligent technology.

Conclusion

It represents more than a technical upgrade — it’s a complete rethinking of how air and friction interact in mechanical systems. By combining tribological science with pneumatic engineering, it offers a solution that’s efficient, sustainable, and built for the future.

From reducing energy consumption to enhancing precision in robotics and automotive systems, Tribupneu stands out as one of the most promising innovations in modern mechanical design.

For industries looking to cut costs, extend equipment life, and move toward eco-friendly operations, embracing Tribupneu could be a defining step forward.

FAQs

What does Tribupneu mean?

It combines tribology (friction study) and pneumatics (air systems) into one efficient mechanism.

How is it different from regular pneumatics?

It manages both airflow and surface friction, leading to smoother and more efficient motion.

Is Tribupneu energy-efficient?

Yes, it reduces air loss and power consumption while maintaining strong mechanical output.

Can it be used in robotics?

Absolutely — its precision and smooth motion make it ideal for robotic and automated systems.

Does it need much maintenance?

No. Tribupneu’s friction-control design helps extend service intervals and reduces wear.